产品介绍 / PRODUCT INTRODUCTION

单筒烘干机是金万泓机械的核心产品,它集高效干燥、节能和环保于一体,广泛应用于生物质能源、 饲料生产、化学工业、矿业、建筑材料等众多行业。单筒烘干机是烘干高湿度和高粘度物料的优选设 备,可根据不同物料的特性匹配多种内叶片结构和布局形式。它被划分为多种干燥模式,并具有广泛 的进料适应性。单筒式烘干机具有高效干燥、成品均匀干燥、结构坚固运行稳定可靠、维护简单以及 低能耗等特点。

The ingle drum dryer is the core product of Jinwanhong Machinery, which integrates efficient drying, energy saving, and environmental pr otection. It is widely used in many industries such as biomass energy, feed production, chemical industry, mining, and building materials. Single drum dryer is the preferred equipment for drying high humidity and high viscosity materials, and can match various internal blade structures and layout forms according to the characteristics of differ- ent materials. It is divided into multiple drying modes and has a wide range of feed adaptability. The single drum dryer has the characteristics of efficient drying, uniform drying of finished prod- ucts, sturdy structure, stable and reliable operation, simple maintenance, and low energy consumption.

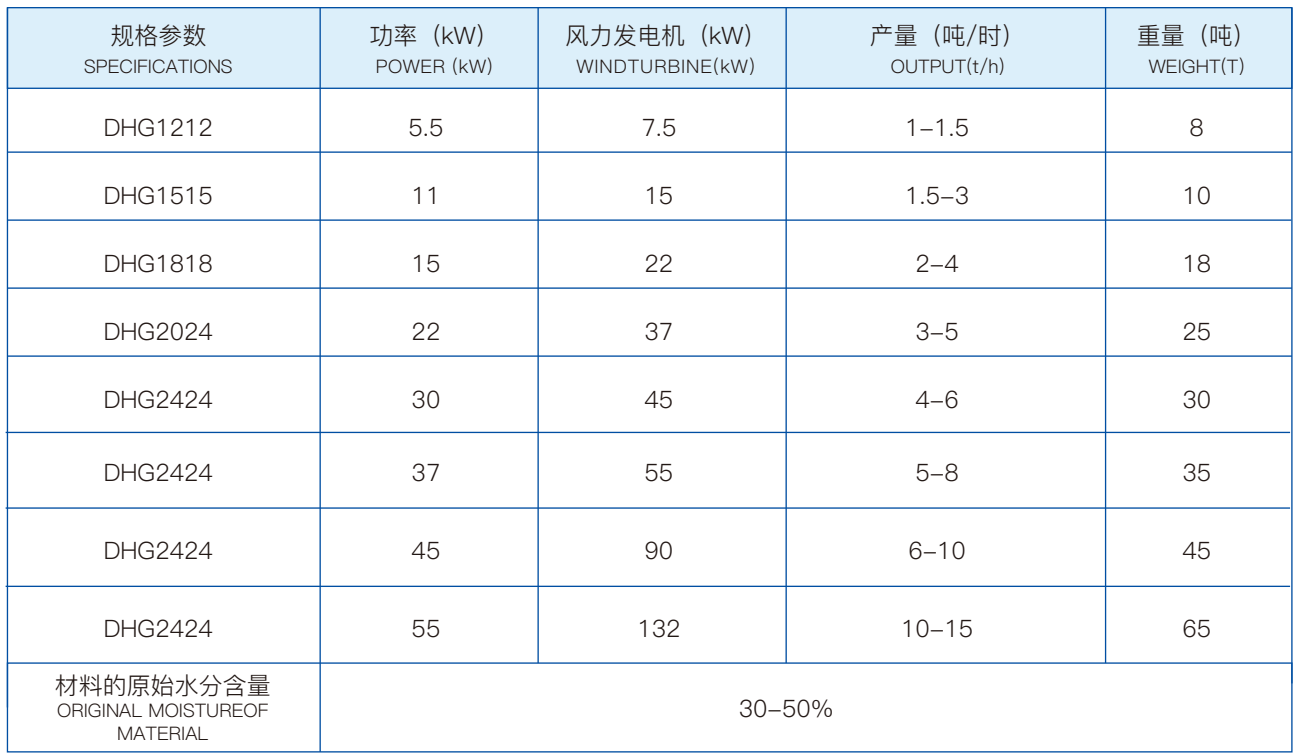

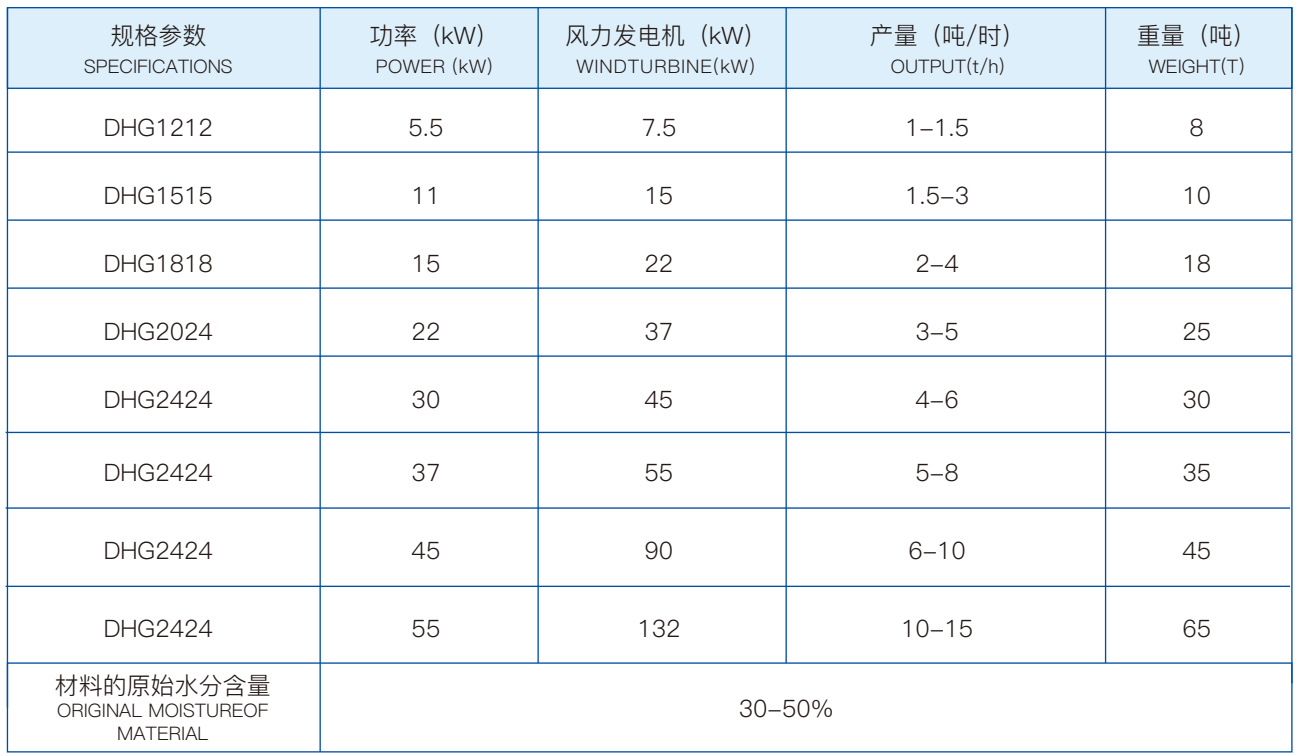

技术参数 / TECHNICAL PARAMETER

技术优势 / TECHNICAL ADVANTAGES

(1)先进的单缸设计

优化的单筒结构设计,显著增强了热风与物料的接触效率和均匀性。独特的内部流场引导热风与物料 充分、持久的混合,大幅提升热能利用效率,缩短干燥周期。同时,精妙的热风分布与物料运动协 同,有效消除了局部过干或受热不均问题,确保物料整体一致干燥,成品品质稳定均一。

(1)ADVANCED SINGLE-CYLINDER DESIGN

The optimized single tube structure design significantly enhances the contact efficiency and uniformity between hot air and materials. The unique internal flow field guides the thorough and persistent mixing of hot air and materials, greatly improving the efficiency of thermal energy utilization and shortening the drying cycle. At the same time, the exquisite distribution of hot air and the coordination of material movement effectively eliminate the problems of local over drying or uneven heating, ensuring that the material is uniformly dried as a whole and the quality of the finished product is stable and uniform.

(2)高效节能

显著提升能效,降低运营成本: 通过结构优化与先进热力学设计,本方案集成了高效热能回收利用系 统,可显著降低整体能耗约20%。精密的温度与气流调控机制,不仅保障了物料热风接触的充分性与 干燥的均匀性,更有效捕获并循环利用排气余热,大幅减少热能浪费。这使得单位产能的能源消耗得 以显著下降,为客户带来实质性的运营成本节约。其优化的热能管理在维持高性能输出的同时,持续 降低用户的长期能源成本负担。

(2)EFFICIENT AND ENERGY-SAVING

Significantly improving energy efficiency and reducing operating costs: Through structural optimi- zation and advanced thermodynamic design, this solution integrates an efficient heat recovery and utilization system, which can significantly reduce overall energy consumption by about 20%. The precise temperature and airflow control mechanism not only ensures sufficient hot air contact and uniform drying of materials, but also effectively captures and recycles exhaust waste heat, greatly reducing thermal energy waste. This significantly reduces energy consumption per unit of produc- tion capacity, bringing substantial operational cost savings to customers. Its optimized thermal energy management maintains high-performance output while continuously reducing the long-term energy cost burden on users.

(3)易于操作

集成化智能控制系统配备用户友好操作界面,显著提升设备启动与操作便捷性。通过预设程序与自动 化运行管理,大幅减少人工干预需求,实现设备运行的高效调度与稳定性保障,显著提升生产线的连 续生产能力和整体效率。

(3)EASY TO OPERATE

The integrated intelligent control system is equipped with a user-friendly interface, significantly improving the convenience of device startup and operation. By pre-set programs and automated operation management, the need for manual intervention is significantly reduced, achieving efficient scheduling and stability assurance of equipment operation, and significantly improving the continuous production capacity and overall efficiency of the production line.

(4)耐用可靠

关键部件选用高强度特种耐磨材料,显著延长设备核心使用寿命。这不仅大幅减少维护频次,更有效 降低了长期运行中的综合维护成本。

(4)DURABLE AND RELIABLE

The key components are made of high-strength special wear-resistant materials, significantly extending the core service life of the equipment. This not only significantly reduces maintenance frequency, but also effectively lowers the overall maintenance cost during long-term operation.

(5)环保设计

集成高效除尘系统搭配先进节能技术,显著减少废气排放,确保符合严格环保要求。此双重设计有效 支持企业降低环境影响,助力可持续生产与绿色发展战略的实现。

(5)ENVIRONMENTAL-FRIENDLY DESIGN

The integrated high-efficiency dust removal system combined with advanced energy-saving tech- nology significantly reduces exhaust emissions and ensures compliance with strict environmental protection requirements. This dual design effectively supports enterprises in reducing environmen- tal impact and helps achieve sustainable production and green development strategies.

案例背景 / CASE BACKGROUND

该牧场主要从事畜牧业,生产牲畜饲料。其饲料原料主要包括秸秆和牧草,干燥处理是生产过程中至 关重要的步骤。此前使用的传统烘干设备存在干燥不均匀、能耗高的问题,导致饲料水分控制不佳, 影响了饲料的质量和牲畜的食用效果。为此,公司决定引入金万泓机械的单筒烘干机来提升秸秆和牧 草的干燥效率和质量。

The ranch is mainly engaged in animal husbandry and produces livestock feed.Its feed raw materi- als mainly include straw and pasture, drying treatment is a crucial step in the productionprocess. The traditional drying equipment used previously had the problems of uneven drying and highener- gy consumption, which led to poor control of the feed moisture, affecting the quality of the feed and theeffect of livestock consumption. Therefore, the company decided to introduce jinwanhong Machinery'ssingle cylinder dryer to improve the drying efficiency and quality of straw and forage.

解决方案 / SOLUTION

金万泓机械为其提供了一台定制的单筒烘干机,专为秸秆和牧草类饲料原料的干燥设计。设备采用先 进的滚筒干燥技术,确保热风与原料充分接触,使其快速去除水分,保持物料的均匀干燥。此外,设 备的智能控制系统能够根据不同的饲料原料调节温度和风速,确保水分控制在饲料加工所需的最佳水 平。

improved drying efficiency: The drying efficiency of straw and pasture is improved by 30%,which greatly shortens the drying time and meets the feed production needs of the farm.Precise moisture control: The equipment accurately controls the moisture of raw materials to ensure that themoisture content of the feed is stabilized at 12-15%, which improves the palatability and nutri- tional reten-tion of the feed.

实施效果 / IMPLEMENTATION EFFECT 干燥效率提升:秸秆和牧草的干燥效率提升了30%,大大缩短了干燥时间,满足了牧场的饲料生产需

求。

IMPROVED DRYING EFFlClENCY: The drying efficiency of straw and pasture is improved by 30%,which greatly shortens the drying time and meets the feed production needs of the farm.

用户反馈 / CUSTOMER FEEDBACK

内蒙古牧场对金万泓机械的单筒烘干机给予了高度评价。该设备大幅提高产能,显著提升了饲料生产 效率,能够高效完成干燥任务。 同时,在加工过程中,设备有效保障了饲料的高品质,其热敏性营养 物质得以完整保留。 机械运行十分稳定,可满足长时间连续运转需求。日常维护操作简单,易损件的 更换也非常快捷。综合来看,这些优势共同降低了牧场的整体运营成本,使得单位能耗显著下降。 鉴 于此,牧场决定在未来的饲料生产规模扩展项目中,继续引入金万泓的系列设备。

Inner Mongolia Ranch highly praised Jin Wanhong Machinery's single drum dryer. This equipment significantly increases production capacity, significantly improves feed production efficiency, and can efficiently complete drying tasks. Meanwhile, during the processing, the equipment effectively ensures the high quality of the feed, and its thermosensitive nutrients are fully preserved. The mechanical operation is very stable and can meet the demand for long-term continuous operation. The daily maintenance operation is simple, and the replacement of vulnerable parts is also very fast. Overall, these advantages have collectively reduced the overall operating costs of the ranch, resulting in a significant decrease in unit energy consumption. In view of this, the ranch has decid- ed to continue introducing Jin Wanhong's series of equipment in future feed production scale expansion projects.

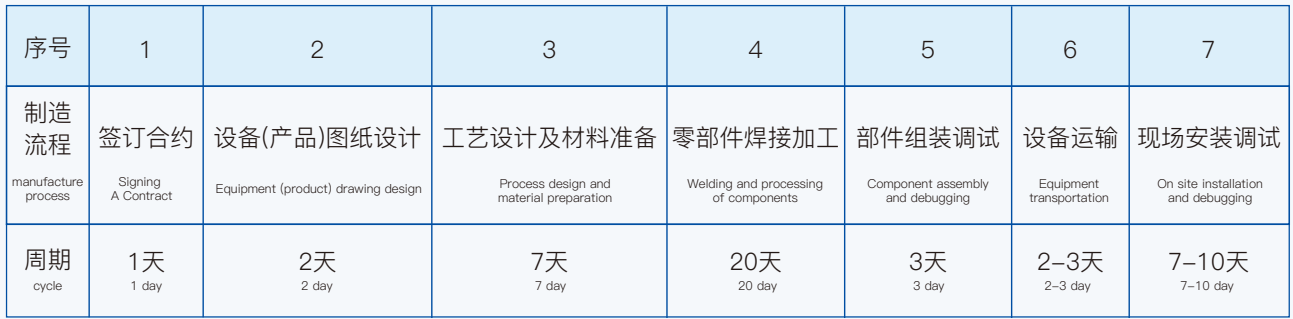

生产进度表 / PRODUCTION SCHEDULE

售后服务承诺 / AFTER SALES SERVICE COMMITMENT

1、本公司提供的设备保证是全新、技术先进、运行可靠的,并能满足双方签订的设备合同及技术协议 的要求。

2、本公司分批提供满足设计、施工、运行和维护所需的图纸、资料和技术文件。 3、本公司售后人员专职负责设备的现场服务工作,将免费指导需方按照技术要求进行设备的按照、调 试和试运行,并负责解决在上述工程中出现的制作和性能等相关问题。并保证当需方提出任何技术疑 问时,在12小时内给予明确答复,48小时内到达供货现场。 4、设备投运一年内,本公司保证各项技术指标满足规定要求;在设备投运一年内,在正常使用条件下 发生质量问题,本公司无偿提供维修和售后服务。

1. The equipment provided by our company is guaranteed to be brand new, technologically advanced, and reliable in operation, and can meet the requirements of the equipment contract and technical agreement signed by both parties.

2. Our company provides drawings, materials, and technical documents in batches to meet the requirements of design, construction, operation, and maintenance.

3. Our company's after-sales personnel are dedicated to on-site service of equipment, providing free guidance to the demand side on equipment compliance, debugging, and trial operation according to technical requirements. They are also responsible for resolving production and performance related issues that arise in the aforementioned projects. And guarantee to provide a clear response within 12 hours and arrive at the supply site within 48 hours when the demand side raises any technical questions.

4. Within one year of equipment operation, our company guarantees that all technical indicators meet the specified requirements; Within one year of equipment operation, if quality problems occur under normal usage conditions, our company will provide free maintenance and after-sales service.