金万泓机械 2024年11月15日 18:24 山东

在当今竞争激烈的工业环境中,高效、智能化的生产线是企业提升生产效率、降低运营成本、确保产品质量的关键。金万泓机械有限公司凭借卓越的研发实力和不断创新的技术,推出了先进的全自动生产线,为各行业客户提供一站式、定制化的生产解决方案,助力企业实现智能化生产和可持续发展。

In today's competitive industrial environment, an efficient and intelligent production line is the key for enterprises to improve production efficiency, reduce operating costs and ensure product quality.With outstanding research and development capabilities and innovative technology,Jinwanhong Machinery Co., Ltd. has launched its advanced fully automated production line.providing one-stop and customized production solutions for customers in various industries, helping enterprises achieve intelligent production and sustainable development.

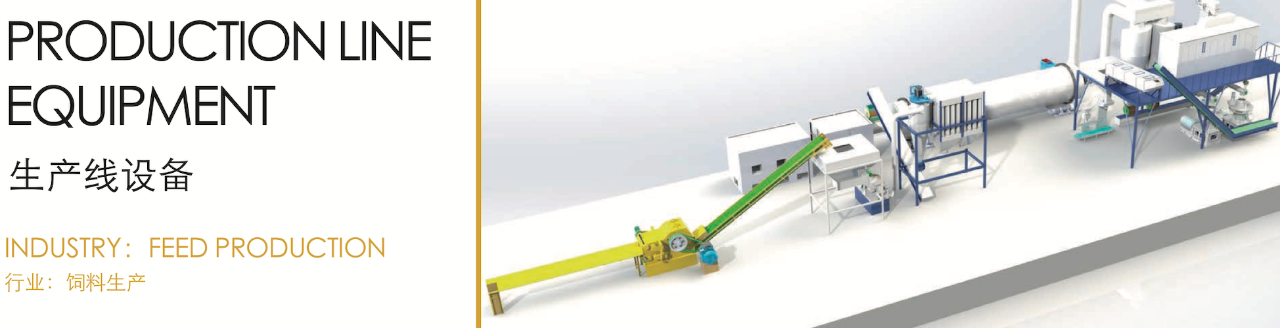

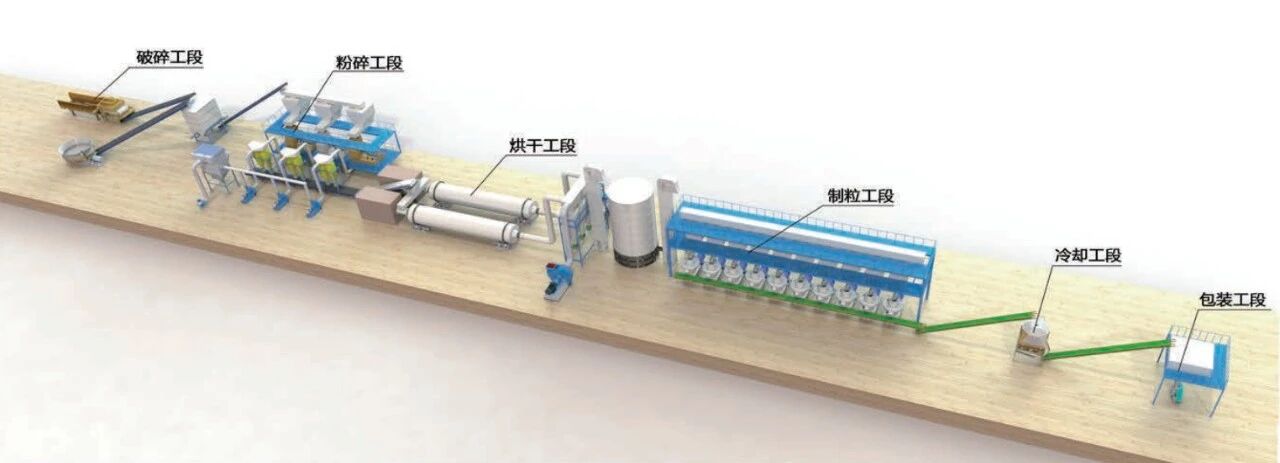

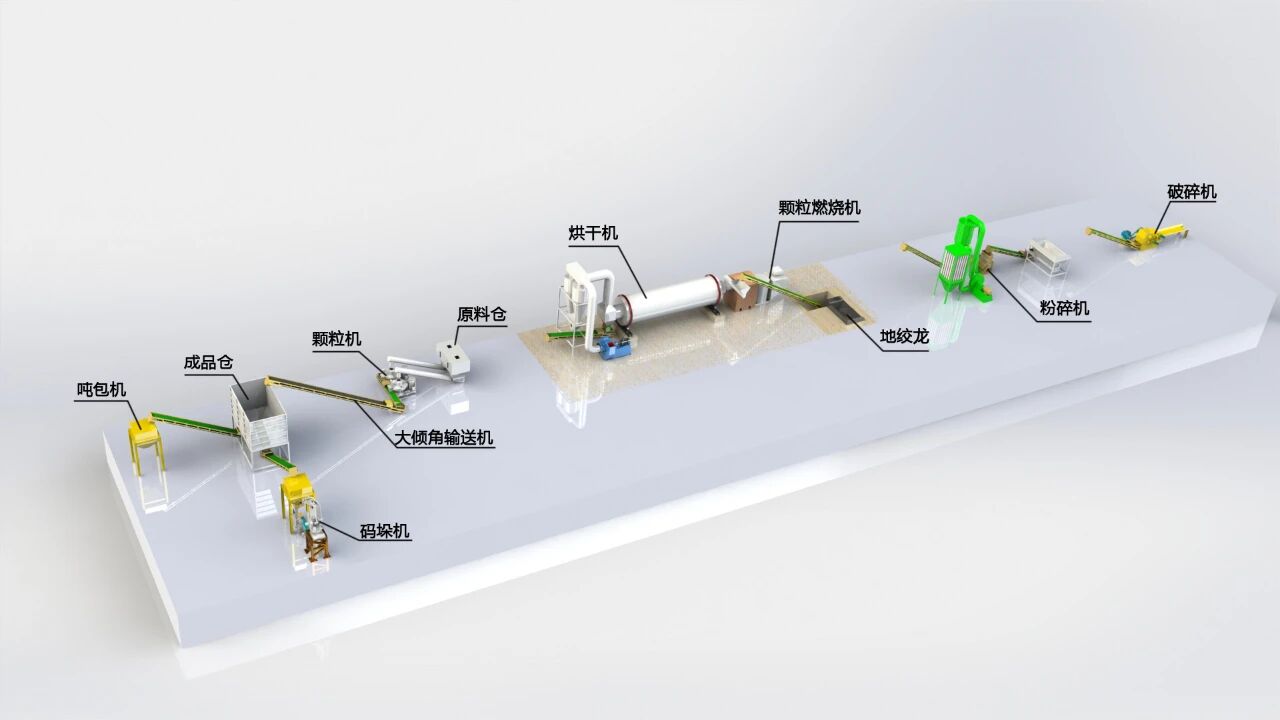

全自动生产线是金万泓机械有限公司的旗舰产品,集多种高效机械设备于一体,涵盖烘干、破碎、粉碎、颗粒化、燃烧等多个工艺环节。该生产线根据客户的具体需求进行定制,确保每一条生产线都能最大化地满足客户的生产要求,提高生产效率,降低人工成本,实现自动化、智能化生产。

As a flagship product, Jinwanhong Machinery’s Fully automated production line integrates a variety of efficient mechanical equipment, covering drying, crushing, pulverizing, granulation, combustion and other processes. The production line is customized according to the specific needs of customers to ensure that each production line can maximize the customer's production requirements, improve production efficiency, reduce labor costs, and realize automated and intelligent production.

1.模块化设计

灵活配置:根据客户需求,灵活配置不同模块,满足不同生产工艺的需求。

便于扩展:模块化设计便于后续扩展和升级,适应企业不断发展的生产需求。

2.高效节能

优化能耗:采用先进的节能技术,优化热能和电能的利用,降低整体能耗。

环保高效:减少废气、粉尘等污染物排放,符合国家环保标准,助力企业绿色生产。

3.智能控制系统

全自动操作:集成PLC智能控制系统,实现生产过程的全自动化控制,减少人工干预,提高生产效率。

数据监控:实时监控生产数据,提供精准的生产管理和优化建议。

4.耐用可靠

高强度材料:采用高强度耐磨材料制造,确保设备长期稳定运行,减少维护频率和成本。

稳定性能:多重安全保护设计,确保设备在各种工况下稳定运行。

5.易于维护

便捷维修:模块化设计和易拆卸结构,便于日常维护和故障排查,减少设备停机时间。

远程支持:提供远程技术支持,快速响应客户需求,确保生产线的持续稳定运行。

1.Modular design

Flexible configuration:

Flexibly configure different modules to meet customer needs and the requirements of different production processes.

Easy to expand: Modular design is convenient for subsequent expansion and upgrading, adapting to the continuous development of the enterprise's production needs.

2.High efficiency and energy saving

Optimize energy consumption: Adopt advanced energy-saving technology to optimize the utilization of thermal and electrical energy, and reduce overall energy consumption.

Environmentally friendly and efficient: Reduce emissions of pollutants such as exhaust gas and dust, comply with national environmental standards, and assist enterprises in green production.

3.Intelligent control system

Fully automated operation: Integrated with PLC intelligent control system, achieving fully automated control of the production process, reducing manual intervention, and improving production efficiency.

Data monitoring: Real time monitoring of production data, providing accurate production management and optimization suggestions.

4.Durable and reliable

High-strength materials: Made of high-strength wear-resistant materials to ensure the long-term stable operation of the equipment, reducing the frequency and cost of maintenance.

Stable performance: Multiple safety protection design ensures stable operation of the equipment under various working conditions.

5.Easy maintenance

Convenient maintenance: Modular design and easy to disassemble structure facilitate daily maintenance and troubleshooting, reducing equipment downtime.

Remote support: Provide remote technical support, quick response to customer needs, to ensure the continuous and stable operation of the production line.

高产能:多模块组合,满足不同规模生产需求,显著提升整体产能。

节能环保:优化的能耗设计和环保技术,降低生产成本,减少环境负担。

质量稳定:精确的控制系统和高效设备,确保产品质量和生产稳定性。

智能化管理:先进的智能控制系统,实现生产过程的自动化和数据化管理,提升管理效率。

维护便捷:模块化和易拆卸设计,简化维护流程,减少设备停机时间。

High capacity: Multiple module combinations meet the production needs of different scales, significantly improving overall production capacity.

Energy saving and environmental-friendly: Optimized energy consumption design and environmental protection technology reduce production costs and environmental burden.

Stable quality: Accurate control system and efficient equipment ensure product quality and production stability.

Intelligent management: Advanced intelligent control system realizes automation and data management of the production process and improves management efficiency.

Convenient maintenance: Modularization and easy to disassemble design simplifies maintenance processes and reduces equipment downtime.

客户名称:新疆某大型畜牧业公司

行业:饲料生产

案例背景:

该公司是一家主要从事饲料生产和牲畜养殖的企业。牧场的饲料生产主要依赖于秸秆和牧草,这些原料在制作饲料前必须进行干燥处理。由于该公司生产规模大,之前的分散式烘干设备效率低、能耗高,且干燥不均匀,影响了饲料的品质和产量。为了提升生产效率和产品质量,公司决定引入金万泓机械的全自动生产线设备,用于秸秆和牧草的烘干及加工。

解决方案:

金万泓机械为该公司设计并安装了一条全自动生产线,涵盖秸秆与牧草的烘干、粉碎、混合及饲料成型的完整工艺流程。生产线中的核心设备是高效节能的单筒烘干机,配合自动送料系统,确保秸秆和牧草在加工过程中的均匀干燥。同时,整条生产线采用智能化控制系统,能够根据不同的饲料原料和生产需求自动调节温度、风速和生产节奏,确保生产效率和饲料品质。

实施效果:

生产效率大幅提升:全自动生产线投入使用后,秸秆和牧草的干燥及饲料加工效率提升了40%,大大缩短了生产周期,满足了大规模生产需求。

水分控制精准:生产线的智能控制系统精确调节干燥过程,确保饲料原料的水分含量稳定在12-15%,大幅提升了饲料的质量和适口性。

一体化自动化生产:整条生产线实现了从烘干、粉碎、混合到成型的全自动化操作,减少了人工干预,降低了劳动强度,提升了生产线的整体稳定性。

能耗降低:得益于生产线的节能设计,整体能耗减少了22%,有效降低了公司在大规模生产中的运营成本。

客户反馈:

新疆畜牧业公司对金万泓提供的全自动生产线设备非常满意。设备显著提升了饲料生产的效率和饲料品质,特别是秸秆和牧草的干燥效果非常理想,饲料的适口性和营养价值明显提高。公司管理层对设备的智能化控制和低能耗设计表示高度认可,并计划在未来的扩产计划中继续采购金万泓的生产线设备。

Customer name: A large-scale animal husbandry company in Xinjiang

Industry:Feed production

Case background:

The company is an enterprise mainly engaged in feed production and livestock breeding. The feed production of the ranch mainly relies on straw and pasture, and these raw materials must be dried before making feed. Due to the company's large production scale, the previous decentralized drying equipment had low efficiency, high energy consumption and uneven drying, which affected the quality and yield of feed. In order to improve production efficiency and product quality, the company decided to introduce the fully automated production line equipment from Jinwanhong Machinery for drying and processing straw and forage.

Solution:

Jinwanhong Machinery designed and installed a fully automated production line for the company, covering the complete process of straw and forage drying, pulverizing, mixing and feed molding. The core equipment of the production line is the energy-efficient single cylinder dryer, which, together with the automatic feeding system, ensures the uniform drying of straw and forage in the process. At the same time, the whole production line adopts intelligent control system, which can automatically adjust the temperature, wind speed and production rhythm according to different feed materials and production requirements, ensuring production efficiency and feed quality.

Implementation effect:

Significant increase in production efficiency: After the fully automated production line is put into use, the drying of straw and forage and feed processing efficiency has been increased by 40%, which greatly shortens the production cycle and meets the demand for large-scale production.

Precise moisture control: The intelligent control system of the production line precisely regulates the drying process to ensure that the moisture content of the feed material is stabilized at 12-15%, which greatly improves the quality and palatability of the feed.

Integrated automated production: The whole production line realizes fully automated operation from drying, pulverizing, mixing to molding, which reduces manual intervention, lowers labor intensity and improves the overall stability of the production line.

Reduced energy consumption: Thanks to the energy-saving design of the production line, the overall energy consumption has been reduced by 22%, which effectively reduces the company's operating costs in large-scale production.

Customer feedback:

The Xinjiang animal husbandry companyis very satisfied with the fully automated production line equipment provided by Jinwanhong. The equipment significantly improves the efficiency of feed production and feed quality, especially the drying effect of straw and forage is very ideal, and the palatability and nutritional value of feed is obviously improved. The management of the company highly recognized the intelligent control and low energy consumption design of the equipment, and planned to continue to purchase Jinwanhong's production line equipment in the future expansion plan.