方案概况 / OVERVIEW OF THE PLAN

产品介绍 / PRODUCT INTRODUCTION

三筒内循环烘干机是我公司针对目前单筒烘干机产量低,占地面积大,基础投资大等缺点研制开发的 新型烘干设备,具有节能、环保、高效的优点,主要用于沙、煤、矿渣、铁粉等原料的烘干;也适用 于化工行业的磷肥、复合肥生产的原料烘干和生物质行业各种木质散装物料的烘干。

The three cylinder internal circulation dryer is a new type of drying equipment developed by our company in response to the current shortcomings of low output, large footprint, and high basic investment of single cylinder dryers. It has the advantages of energy saving, environmental protec�tion, and high efficiency, and is mainly used for drying raw materials such as sand, coal, slag, and iron powder; It is also applicable to the drying of raw materials for the production of phosphate fertilizers and compound fertilizers in the chemical industry, as well as the drying of various wooden bulk materials in the biomass industry.

三筒烘干机的烘干过程是这样实现的:被烘干的物料由入料端喂入烘干机内筒,物料通过内筒的螺旋 导向板进入内筒,内筒内部设有许多螺旋状扬料板,物料通过筒体的回转,被扬料板不断地扬起并做 纵向运动,物料到达内筒的右端因自重的作用落入中筒,通过螺旋导向板,在筒体回转作用下物料被 推回中筒,在中筒扬料板的作用下物料向左运动,直到中筒的左端,物料在自重作用下落入外筒。同 样道理,物料在外筒螺旋扬料板的作用下折回向右运动,直到外筒右端。在封堵外导料锥的作用下落 入出料端筒体内。烘干机主体的三个同心圆筒内,设有不同数量、不同角度的曲面螺旋状扬料板,每 个筒体的端部设有螺旋导向板。

The drying process of a three cylinder dryer is achieved as follows: the dried material is fed into the inner cylinder of the dryer from the feeding end, and the material enters the inner cylinder through the spiral guide plate of the inner cylinder. There are many spiral shaped lifting plates inside the inner cylinder, and the material is continuously lifted and moved longitudinally by the lifting plates through the rotation of the cylinder. The material reaches the right end of the inner cylinder and falls into the middle cylinder due to its own weight. Through the spiral guide plate, the material is pushed back to the middle cylinder under the rotation of the cylinder. The material moves left under the lifting plate of the middle cylinder until it falls into the outer cylinder under its own weight. Similarly, the material is folded back and moves to the right under the action of the spiral lifting plate on the outer cylinder until it reaches the right end of the outer cylinder. Under the action of blocking the outer guide cone, it falls into the discharge end cylinder. Inside the three concentric cylinders of the dryer body, there are different numbers and angles of curved spiral lifting plates, and each end of the cylinder is equipped with a spiral guide plate.

三筒烘干机的主体通过四个减速电机,分别驱动两端的四个传动拖轮,使轮带绕中心转动。待烘干 机的湿物料经喂料设备进入筒体内,随着筒体的旋转,物料不断的翻滚、抛撒并向出料端纵向运 动,与此同时从热风炉来的热气流,先后进入内筒中筒外筒与物料进行强烈的热交换。由于金属钢 板比被烘干的物料导热快,筒体的钢板、扬料板首先受热,然后又把热量以传导和辐射的方式传给 物料,物料受热厚温度升高,水蒸气从物料中分离出来,随烟尘经除尘器后排入大气中,从而达到 物料烘干的目的。

The main body of the three cylinder dryer is driven by four reduction motors, which respectively drive the four transmission tugboats at both ends, causing the wheel belt to rotate around the center. The wet material to be dried enters the cylinder through the feeding device. As the cylin�der rotates, the material continuously rolls, scatters, and moves longitudinally towards the discharge end. At the same time, the hot air flow from the hot air stove enters the inner cylinder, middle cylinder, and outer cylinder for strong heat exchange with the material. Due to the faster thermal conductivity of metal steel plates compared to the materials being dried, the steel plates and lifting plates of the cylinder are first heated, and then the heat is transferred to the materials through conduction and radiation. The temperature of the materials increases as they are heated, and water vapor is separated from the materials. After passing through the dust collector with the smoke and dust, it is discharged into the atmosphere, thus achieving the purpose of material drying.

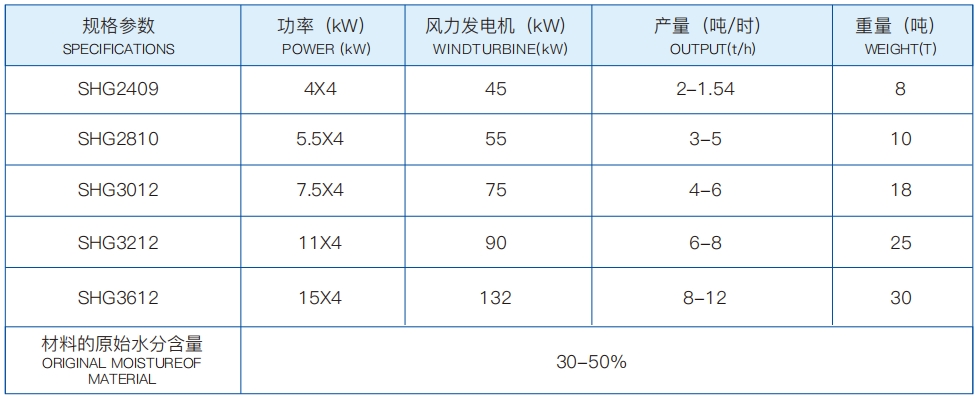

技术参数 / TECHNICAL PARAMETER

三筒烘干机的优点 / THE ADVANTAGES OF A THREE CYLINDER DRYER

1、技术含量高,筒体自我保温,热效率高达75%(单筒烘干机热效率仅为35%-40%),比单筒烘干节煤68%。

2、比单筒烘干机整机长度缩短50%,有利于工艺布置。减少厂房建筑面积,对设备土建基础要求低,节约工程投资。

3、采用耐热耐磨合金钢板,比普通钢板耐磨2倍以上,使用寿命长。

4、热效率高,外筒体温度低于60℃(单筒烘干机外筒体温度高达150℃),出口温度低,出料温度低于80℃。

5、出气温度低,有利于除尘设备使用时间,可直接配套脉冲布袋除尘器。

6、无需大小齿轮传动,采用拖轮传动,结构简单,易损件少。

1. High technical content, self insulation of the cylinder body, thermal efficiency up to 75% (the thermal efficiency of a single cylinder dryer is only 35% -40%), saving 68% coal compared to single cylinder drying.

2. Shortening the overall length of a single drum dryer by 50% is beneficial for process layout. Reduce the building area of the factory, lower the requirements for equipment civil engineering foundation, and save engineering investment.

3. Made of heat-resistant and wear-resistant alloy steel plate, it is more than twice as wear-resistant as ordinary steel plate and has a longer service life.

4. High thermal efficiency, outer cylinder temperature below 60 ℃ (single drum dryer outer cylinder temperature up to 150 ℃), low outlet temperature, and discharge temperature below 80 ℃.

5. Low exhaust temperature is beneficial for the use time of dust removal equipment and can be directly matched with pulse bag dust collectors.

6. No need for gear transmission, using tugboat transmission, simple structure, and few vulnerable parts.

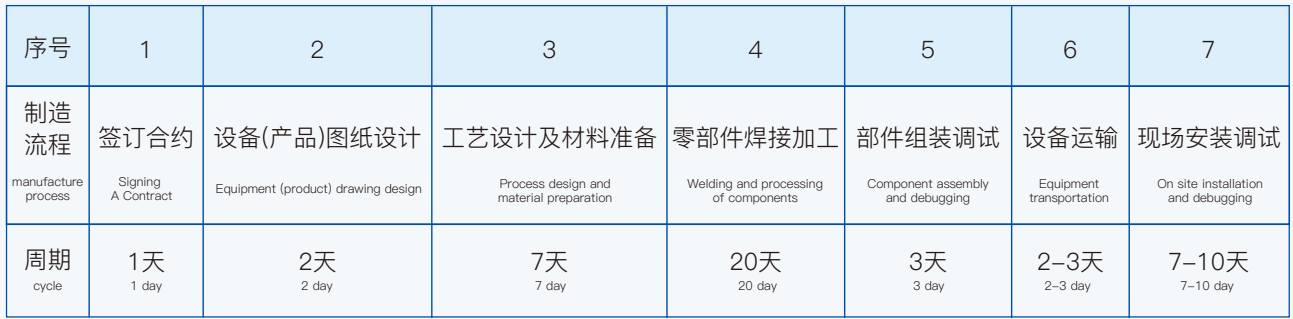

生产进度表 / PRODUCTION SCHEDULE

售后服务承诺 / AFTER SALES SERVICE COMMITMENT

1、本公司提供的设备保证是全新、技术先进、运行可靠的,并能满足双方签订的设备合同及技术协议 的要求。

2、本公司分批提供满足设计、施工、运行和维护所需的图纸、资料和技术文件。

3、本公司售后人员专职负责设备的现场服务工作,将免费指导需方按照技术要求进行设备的按照、调 试和试运行,并负责解决在上述工程中出现的制作和性能等相关问题。并保证当需方提出任何技术疑 问时,在12小时内给予明确答复,48小时内到达供货现场。

4、设备投运一年内,本公司保证各项技术指标满足规定要求;在设备投运一年内,在正常使用条件下 发生质量问题,本公司无偿提供维修和售后服务。

1. The equipment provided by our company is guaranteed to be brand new, technologically advanced, and reliable in operation, and can meet the requirements of the equipment contract and technical agreement signed by both parties.

2. Our company provides drawings, materials, and technical documents in batches to meet the requirements of design, construction, operation, and maintenance.

3. Our company's after-sales personnel are dedicated to on-site service of equipment, providing free guidance to the demand side on equipment compliance, debugging, and trial operation according to technical requirements. They are also responsible for resolving production and performance related issues that arise in the aforementioned projects. And guarantee to provide a clear response within 12 hours and arrive at the supply site within 48 hours when the demand side raises any technical questions.

4. Within one year of equipment operation, our company guarantees that all technical indicators meet the specified requirements; Within one year of equipment operation, if quality problems occur under normal usage conditions, our company will provide free maintenance and after-sales service.