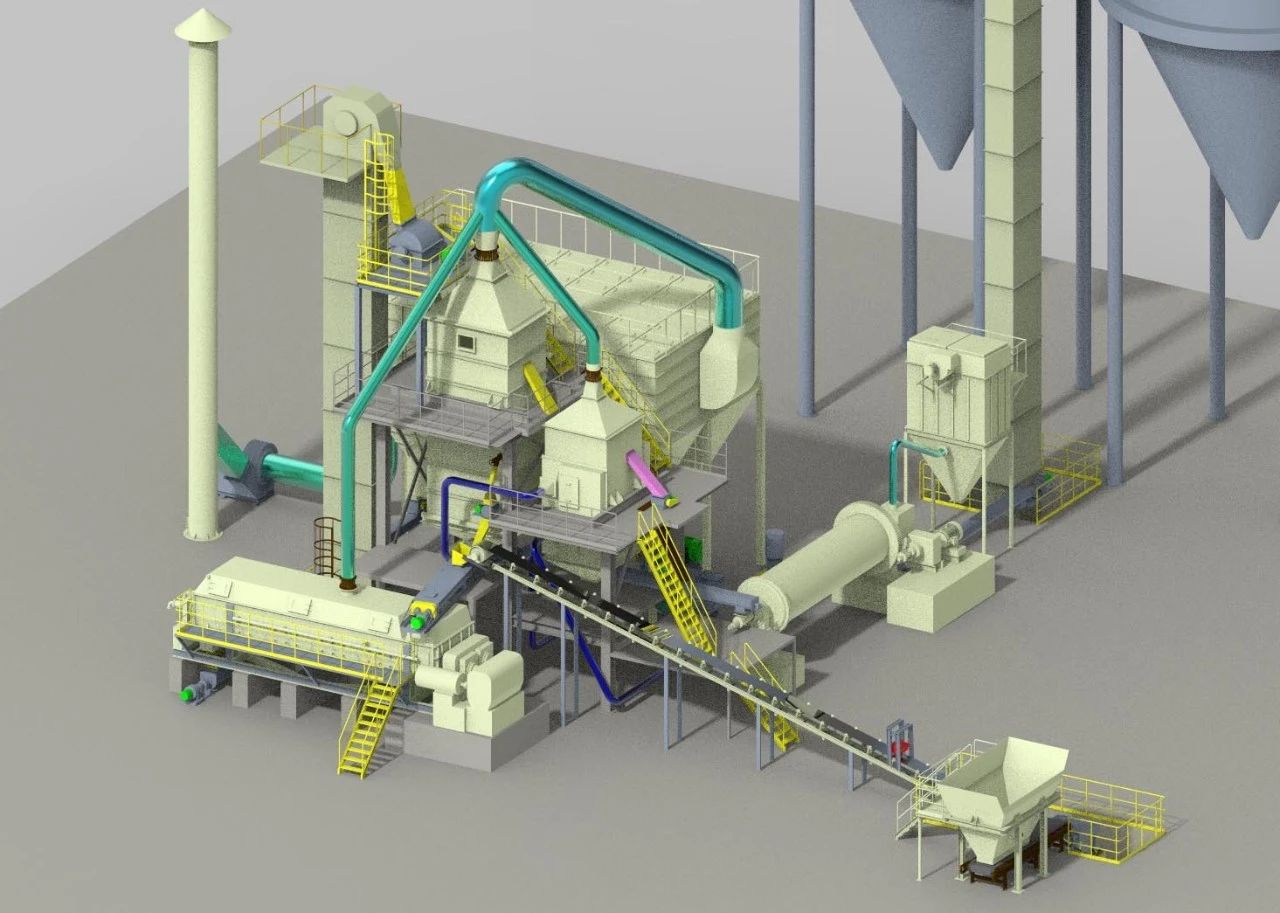

化工生产中,各类高粘性物料的烘干一直是行业难题。传统设备常因物料粘壁、堵塞导致停机维护,不仅影响产能,还存在安全隐患。金万泓针对化工行业特性,推出“防粘设计 + 分级处理” 的定制化方案,通过材料创新与流程优化,为化工企业提供从预处理到成品输出的全链条解决方案。Drying various high viscosity materials has always been a challenge in chemical production. Traditional equipment is often shut down for maintenance due to material sticking or blockage, which not only affects production capacity but also poses safety hazards. Jin Wanhong has launched a customized solution of "anti sticking design+graded treatment" based on the characteristics of the chemical industry. Through material innovation and process optimization, it provides chemical enterprises with a full chain solution from pre-treatment to finished product output.

|

|  |

|

|  |

|

| 化工物料的复杂性体现在两个方面:一是高粘性导致的流动性差,例如印染污泥在烘干过程中易粘附滚筒内壁,形成顽固结块;二是部分物料对温度敏感,高温下易发生分解或变色。某化工企业曾因使用普通烘干机处理树脂废渣,导致设备连续堵塞,月停机时间超过 48 小时,直接经济损失达数十万元。

The complexity of chemical materials is reflected in two aspects: one is the poor fluidity caused by high viscosity, for example, printing and dyeing sludge is prone to adhere to the inner wall of the drum during the drying process, forming stubborn clumps; Secondly, some materials are temperature sensitive and prone to decomposition or discoloration at high temperatures. A certain chemical enterprise once experienced continuous equipment blockages due to the use of ordinary dryers to treat resin waste, resulting in monthly downtime of over 48 hours and direct economic losses of hundreds of thousands of yuan. |

|

| |

|

|  |

|

| 为解决物料粘壁问题,金万泓在设备内壁采用特殊防粘涂层,并优化滚筒倾角与转速。例如,在处理含水率较高的化工污泥时,滚筒内壁的“蜂窝状凸起” 设计可增加物料与内壁的摩擦力,使其在重力作用下自然滑落,避免粘附。同时,滚筒内部的链条式扬料板在旋转过程中不断击打筒壁,进一步防止物料堆积。在某染料企业的应用中,这种防粘设计使设备连续运行时间从原来的 3 天延长至 30 天,维护成本降低 60%。企业负责人表示:“以前每星期都要停机清理,现在只需每月检查一次,生产效率大幅提升。”To solve the problem of material sticking to the wall, Jin Wanhong adopts a special anti sticking coating on the inner wall of the equipment and optimizes the inclination angle and speed of the drum. For example, in the treatment of chemical sludge with high moisture content, the "honeycomb shaped protrusion" design on the inner wall of the drum can increase the friction between the material and the inner wall, allowing it to naturally slide under gravity and avoid adhesion. At the same time, the chain type lifting plate inside the drum continuously hits the drum wall during rotation, further preventing material accumulation.In the application of a dye company, this anti sticking design extends the continuous operation time of the equipment from the original 3 days to 30 days, reducing maintenance costs by 60%. The company leader said, "Previously, we had to shut down for cleaning every week, but now we only need to inspect once a month, which greatly improves production efficiency. |

|

| |

|

|  |

|

| 针对化工物料粒径差异大的特点,金万泓在烘干系统中集成气流分级装置。物料在打散后进入分级腔,通过风速调节实现粗细颗粒的分离:粗颗粒返回打散腔再次处理,细颗粒则进入烘干筒进行深度干燥。这种“先打散后分级” 的流程,确保不同粒径的物料在相同时间内达到均匀含水率。某化肥企业在处理磷矿粉时,采用分级处理技术后,成品粒度合格率从 75% 提升至 95%,且能耗降低 22%。该技术不仅适用于化工行业,还可扩展至矿石加工、建材生产等领域,为多行业提供精细化烘干方案。

In response to the large difference in particle size of chemical materials, Jin Wanhong integrates an airflow classification device in the drying system. After being dispersed, the material enters the classification chamber and the separation of coarse and fine particles is achieved through wind speed adjustment: coarse particles return to the dispersion chamber for further processing, while fine particles enter the drying drum for deep drying. This process of "first dispersing and then grading" ensures that materials of different particle sizes achieve uniform moisture content in the same time.After adopting the grading treatment technology in the processing of phosphate ore powder, a certain fertilizer enterprise increased the qualified rate of finished product particle size from 75% to 95%, and reduced energy consumption by 22%. This technology is not only applicable to the chemical industry, but can also be extended to fields such as ore processing and building materials production, providing refined drying solutions for multiple industries. |