In modern industrial production, crushing process is an important link to ensure product quality and production efficiency. Whether it is in the field of biomass energy, feed production, or chemical and mining industries, efficient, energy-saving and eco-friendly crushing equipment can significantly improve production efficiency and reduce operating costs. Since its establishment in 2020, Jinwanhong Machinery Co., Ltd. has launched advanced Wood Chip Machine with outstanding research and development capabilities and continuously innovative technology, providing customers with the best crushing solutions.

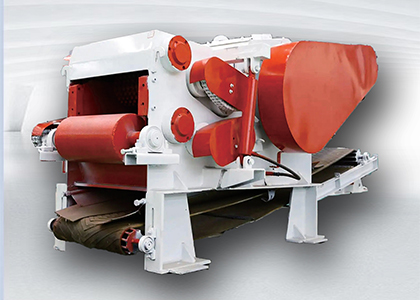

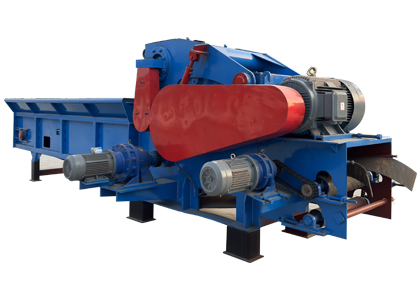

Wood Chip Machine

IMPLEMENTATION EFFECT :

► Improved drying efficiency: The drying efficiency of biomass fuel has been improved by 30%, which meets the company’s demand for expanding production.

► Significant energy saving effect: Compared with traditional equipment, the three-pass dryer saves energy by 20%, significantly reducing the production cost of the enterprise.

► Improved product quality: The moisture content of the dried biomass fuel is uniform, the calorific value and combustion efficiency of the finished product have been greatly improved, and the feedback from customers is very good

Advantages

► High processing efficiency: The three-pass system significantly improves the drying speed and shortens the production cycle to meet the demand of large-scale production.

► Energy saving and emission reduction: Optimized thermal energy utilization and low energy consumption design effectively reduce production costs and environmental burden.

► Quality assurance: Precise temperature and humidity control ensures uniform drying of materials and improves product quality and stability.

► Easy maintenance: Modular design facilitates daily maintenance and troubleshooting, reducing equipment downtime.

Disadvantages

► need storage capacity three times as large as oil’s.

© 2025 Jinwanhong Machinery Co., Ltd. All Rights Reserved.

©️Power By WanShiWu