产品介绍 / PRODUCT INTRODUCTION

蒸汽列管回转干燥机是一种高效的干燥设备,主要用于 对各类物料进行连续干燥处理。其工作原理是利用蒸汽 作为热源,通过列管将热量传递给物料,使物料中的水 分蒸发,从而达到干燥的目的。

Steam tube rotary dryer is an efficient drying equip�ment mainly used for continuous drying of various materials. Its working principle is to use steam as a heat source, transfer heat to the material through pipes, and evaporate the moisture in the material, thereby achieving the purpose of drying.

设备结构 / EQUIPMENT STRUCTURE

1、回转筒体:由优质碳钢或不锈钢制成,内部安装有列管,是物料干燥的主要场所。筒体通过托轮装置支撑,并由传动 装置驱动旋转。

1. Rotary cylinder body: Made of high-quality carbon steel or stainless steel, with internal pipes installed, it is the main place for material drying. The cylinder is supported by a supporting wheel device and driven to rotate by a trans�mission device.

2、列管组件:列管均匀分布在筒体内,蒸汽在管内流动,将热量传递给管外的物料。列管采用特殊的连接方式,确保密 封性能良好,同时便于安装和维护。

2. Tube components: The tubes are evenly distributed inside the cylinder, and steam flows inside the tubes, transfer�ring heat to the material outside the tubes. The column tube adopts a special connection method to ensure good sealing performance and facilitate installation and maintenance.

3、蒸汽分配器:安装在筒体的一端,用于将蒸汽均匀分配到各列管中。蒸汽分配器具有良好的调节性能,可根据物料干 燥的需要调整蒸汽流量。

3. Steam distributor: installed at one end of the cylinder, used to evenly distribute steam into each row of pipes. The steam distributor has good regulating performance and can adjust the steam flow according to the drying needs of the material.

4、传动装置:由电机、减速机、联轴器和齿轮等组成,通过齿轮带动筒体旋转,确保物料在筒体内均匀翻滚,与列管充 分接触,实现高效干燥。

4. Transmission device: It consists of a motor, a reducer, a coupling, and gears, which drive the cylinder to rotate through the gears, ensuring that the material rolls evenly inside the cylinder and fully contacts the tube, achieving efficient drying.

5、进料装置:采用螺旋给料机或皮带输送机,将待干燥物料均匀输送至干燥机内。进料装置可根据物料的特性和生产要 求进行调整,确保进料稳定。

5. Feeding device: A spiral feeder or belt conveyor is used to evenly transport the material to be dried into the dryer. The feeding device can be adjusted according to the characteristics of the material and production requirements to ensure stable feeding.

6、出料装置:位于筒体的另一端,采用螺旋出料机或星形卸料器,将干燥后的物料排出干燥机。出料装置可与后续的输 送设备或储存设备相连接,实现连续化生产。

6. Discharge device: located at the other end of the cylinder, using a spiral discharge machine or star shaped unload�er to discharge the dried material out of the dryer. The discharge device can be connected to subsequent conveying or storage equipment to achieve continuous production.

7、密封装置:在筒体的两端和进料、出料口处设置密封装置,防止蒸汽和粉尘泄漏,保证工作环境的安全和卫生。

7. Sealing device: Sealing devices are installed at both ends of the cylinder and at the feeding and discharging ports to prevent steam and dust leakage, ensuring the safety and hygiene of the working environment.

工作流程 / WORKFLOW

1、进料:待干燥物料由进料装置均匀送入回转干燥机的 筒体内部。

2、加热:蒸汽从蒸汽分配器进入列管,在管内流动过程 中,将热量传递给管外的物料。随着筒体的旋转,物料 在筒体内不断翻滚,与列管充分接触,实现快速加热和 水分蒸发。

3、干燥:物料在加热过程中,水分逐渐蒸发成水蒸气, 水蒸气随着筒体的旋转和气流的作用,从出料口排出。 同时,干燥后的物料在重力和螺旋抄板的作用下,向出 料口移动。

4、出料:干燥后的物料到达出料口,由出料装置排出干 燥机,进入后续的处理环节。

1. Feeding: The material to be dried is uniformly fed into the cylinder of the rotary dryer by the feeding device.

2. Heating: Steam enters the tube from the steam distributor and transfers heat to the material outside the tube during its flow inside the tube. As the cylinder rotates, the material continuously rolls inside the cylinder and comes into full contact with the tube, achieving rapid heating and water evaporation.

3. Drying: During the heating process of the material, the moisture gradually evaporates into water vapor, which is discharged from the discharge port with the rotation of the cylinder and the action of the airflow. At the same time, the dried material moves towards the discharge port under the action of gravity and the spiral plate.

4. Discharge: The dried material reaches the discharge port and is discharged from the dryer by the discharge device, entering the subsequent processing stage.

设备优势 / EQUIPMENT ADVANTAGES

高效节能:采用蒸汽作为热源,热效率高,能够快速将物料中的水分蒸发,降低能耗。同时,列管的 设计增加了传热面积,提高了干燥效率。

Efficient and energy-saving: Using steam as the heat source, it has high thermal efficiency and can quickly evaporate the moisture in the material, reducing energy consumption. At the same time, the design of the tube increases the heat transfer area and improves the drying efficiency.

适应性强:可适用于多种物料的干燥处理,如矿石、煤炭、污泥、化工原料、食品原料等。对于不同 性质的物料,可通过调整蒸汽压力、筒体转速和干燥温度等参数,满足干燥要求。

Strong adaptability: Suitable for drying various materials such as ore, coal, sludge, chemical raw materials, food raw materials, etc. For materials of different properties, drying requirements can be met by adjusting parameters such as steam pressure, cylinder speed, and drying temperature.

干燥效果好:物料在筒体内不断翻滚,与列管充分接触,受热均匀,能够有效避免物料局部过热或干 燥不均匀的问题。干燥后的物料水分含量低,质量稳定。

Good drying effect: The material continuously rolls inside the cylinder, fully contacts the tube, and is evenly heated, which can effectively avoid the problem of local overheating or uneven drying of the material. The moisture content of the dried material is low and the quality is stable.

操作简便:设备自动化程度高,可实现远程控制和自动化操作。操作人员只需通过控制面板即可对设 备进行启动、停止、调整参数等操作,降低了劳动强度。

Easy to operate: The equipment has a high degree of automation and can achieve remote control and automated operation. Operators can start, stop, and adjust parameters of the equipment through the control panel, reducing labor intensity.

维护方便:设备结构简单,各部件易于拆卸和安装,便于维护和检修。

Easy maintenance: The equipment structure is simple, and each component is easy to disassem�ble and install, making it convenient for maintenance and repair.

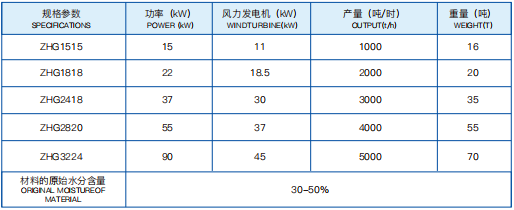

技术参数 / TECHNICAL PARAMETER

客户案例 / CUSTOMER CASE

案例描述:

该化工企业主要生产化肥及其他化工产品,生产过程中涉及大量的湿物料处理。由于传统烘干设备效率低、能耗高,物料 干燥效果不理想,企业面临生产成本高和能耗过大的问题。为此,该公司引入了金万泓机械的蒸汽列管回转干燥机,来提 升干燥效率、降低能耗。 解决方案: 金万泓机械为其提供了一台定制的蒸汽列管回转干燥机。该设备利用蒸汽作为热源,配备高效的列管传热系统,通过旋转 滚筒使物料充分接触加热管束,均匀吸收热量,快速蒸发水分,从而实现高效的干燥过程。 用户反馈: 客户表示,该蒸汽列管回转干燥机在干燥过程中表现出高效、节能、环保等显著优势,设备运行稳定,减少了停机时间和 维护成本。干燥后的物料品质大幅提升,整体生产流程更加顺畅,企业生产效能和经济效益显著提高。这个案例展示了金 万泓机械的蒸汽列管回转干燥机如何在化工行业中帮助客户实现高效干燥、降低能耗,并提升了物料处理的质量和环保表 现。

Case background: The chemical enterprise mainly produces fertilizers and other chemical products, the production process involves a large number of wet materials processing. Due to the low efficiency and high energy consumption of traditional drying equipment, the drying effect of materials is not ideal, and the enterprise faces the problems of high production cost and excessive energy consumption. To this end, The company has introduced the steam tube rotary dryer from Jinwanhong Machinery to improve drying efficiency and reduce energy consumption. Solution: Jinwanhong Machinery has provided a customized steam tube rotary dryer for it. This device uses steam as a heat source and is equipped with an efficient tube bundle heat transfer system. By rotating the drum, the material fully contacts the heating tube bundle, uniformly absorbs heat, and quickly evaporates moisture, thereby achieving an efficient drying process. Customer Feedback: The customer stated that the steam tube rotary dryer exhibits significant advantages such as high efficiency, energy saving, and environmental protection during the drying process. The quality of the dried material is greatly improved, the overall production process is smoother, and the production efficiency and economic benefits of the enterprise are significantly improved.This case demonstrates how Jinwanhong Machinery's steam rotary dryers helps customers achieve efficient drying, reduce energy consumption, and improve material handling quality and environmental perfor�mance in the chemical industry.

售后服务承诺 / AFTER SALES SERVICE COMMITMENT

1、本公司提供的设备保证是全新、技术先进、运行可靠的,并能满足双方签订的设备合同及技术协议的要求。

2、本公司分批提供满足设计、施工、运行和维护所需的图纸、资料和技术文件。

3、本公司售后人员专职负责设备的现场服务工作,将免费指导需方按照技术要求进行设备的按照、调试和试运行,并负 责解决在上述工程中出现的制作和性能等相关问题。并保证当需方提出任何技术疑问时,在12小时内给予明确答复,48小 时内到达供货现场。

4、设备投运一年内,本公司保证各项技术指标满足规定要求;在设备投运一年内,在正常使用条件下发生质量问题,本 公司无偿提供维修和售后服务。

1. The equipment provided by our company is guaranteed to be brand new, technologically advanced, and reliable in operation, and can meet the requirements of the equipment contract and technical agreement signed by both parties.

2. Our company provides drawings, materials, and technical documents in batches to meet the requirements of design, construction, operation, and maintenance.

3. Our company's after-sales personnel are dedicated to on-site service of equipment, providing free guidance to the demand side on equipment compliance, debugging, and trial operation according to technical requirements. They are also responsible for resolving production and performance related issues that arise in the aforementioned projects. And guarantee to provide a clear response within 12 hours and arrive at the supply site within 48 hours when the demand side raises any technical questions.

4. Within one year of equipment operation, our company guarantees that all technical indicators meet the specified requirements; Within one year of equipment operation, if quality problems occur under normal usage conditions, our company will provide free maintenance and after-sales service.