在现代工业生产中,烘干工艺扮演着至关重要的角色。无论是生物质能源、饲料生产,还是化工、矿业等领域,高效、节能、环保的烘干设备都能显著提升生产效率,降低运营成本。金万泓机械有限公司自2020年成立以来,凭借卓越的研发实力和不断创新的技术,推出了先进的蒸汽管束旋转干燥机,为客户提供最佳的烘干解决方案。

In modern industrial production, drying process plays a crucial role.No matter it is in the field of biomass energy, feed production, chemical industry or mining industry, a drying equipment that is highly-efficient, energy-saving and eco-friendly can significantly improve the production efficiency and reduce the operation cost.Since its establishment in 2020, Jinwanhong Machinery Co., Ltd. has launched advancedsteam tube bundle rotary dryer with outstanding research and development capabilities and continuously innovative technology, providing customers with the best drying solutions.

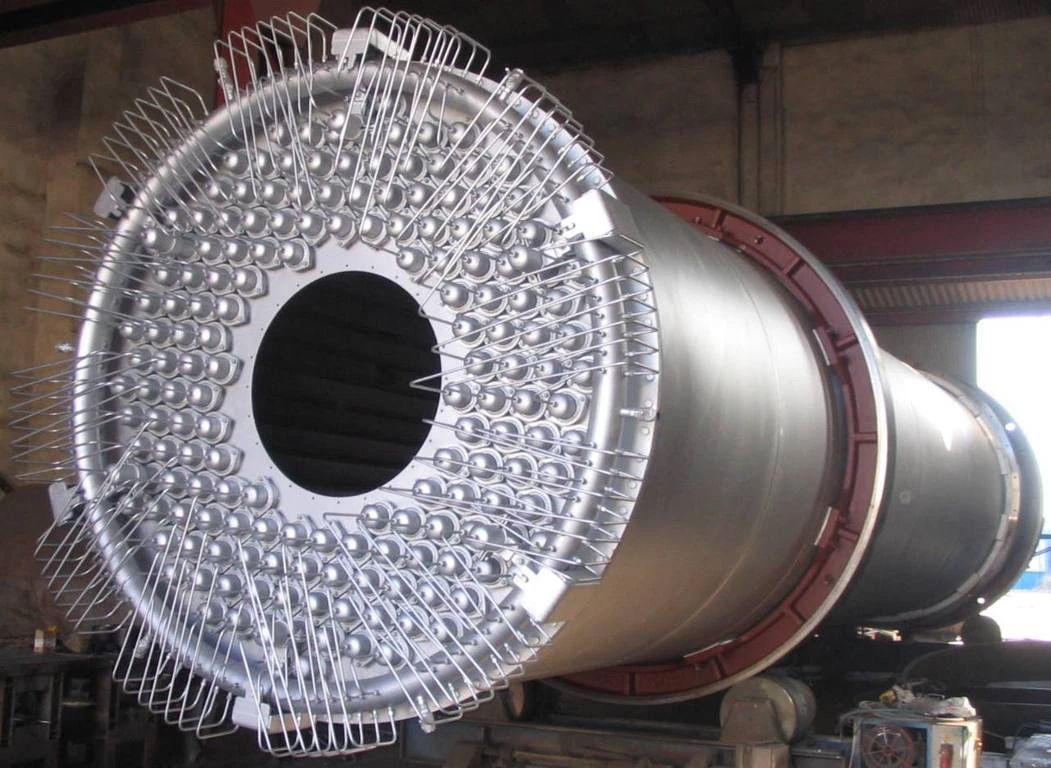

蒸汽管束旋转干燥机是金万泓机械有限公司的一款旗舰产品,集高效烘干、节能环保于一体,广泛应用于生物质能源、饲料生产、化工、矿业、建材等多个行业。该设备采用先进的蒸汽管束技术与旋转干燥工艺,确保物料在高效、均匀的条件下快速干燥,满足不同行业的多样化需求。

Steam tube bundle rotary dryer is a flagship product of Jinwanhong Machinery Co., Ltd, which integrates efficient drying, energy saving and environmental protection, and is widely used in many industries, such as biomass energy, feed production, chemical industry, mining, building materials and so on. This equipment adopts advanced steam bundle technology and rotary drying process to ensure that materials are quickly dried under efficient and uniform conditions, meeting the diverse needs of different industries.

1.先进的蒸汽管束系统

采用高效的蒸汽管束传热技术,确保热能充分传递,提高烘干效率,减少热量损失。2.旋转干燥工艺

独特的旋转设计使物料在烘干过程中不断翻转,确保干燥均匀,避免物料结块。3.高效节能

优化的热能利用设计,使能耗降低20%,为客户节约大量能源成本,同时减少环境负担4.智能控制系统

配备先进的PLC智能控制系统,操作界面友好,易于上手,能够根据物料湿度自动调节温度和风速,提高生产效率。5.耐用可靠

采用高强度耐磨材料制造,延长设备使用寿命,减少维护频率和成本,确保长期稳定运行。6.环保设计

高效的除尘系统和节能技术,减少废气排放,符合国家环保标准,助力企业绿色发展。1.Advanced steam tube bundle systemAdopting highly efficient steam tube bundle heat transfer technology to ensure full transfer of heat energy, improve drying efficiency and reduce heat loss.The unique rotating design continuously flips the material during the drying process, ensuring even drying and avoiding material clumping.3.Efficient and energy-savingOptimized thermal energy utilization design reduces energy consumption by 20%, saving customers a significant amount of energy costs and reducing the burden on the environment at the same time.4.Intelligent control systemEquipped with advanced PLC intelligent control system, the operation interface is user-friendly and easy to start, capable of automatically adjusting temperature and wind speed according to material humidity, improving production efficiency.Adopting high-strength wear-resistant materials to extend the service life of the equipment and reduce the maintenance frequency and cost, and ensure long-term stable operation.6.Environmental-friendly designHigh-efficiency dust removal system and energy-saving technology, reduce exhaust emissions, in line with national environmental standards, help enterprises to realize green development.

处理效率高:蒸汽管束系统与旋转干燥工艺相结合,显著提升烘干速度,缩短生产周期,满足大规模生产需求。节能减排:优化的热能利用和低能耗设计,有效降低生产成本,减少环境负担。质量保证:精确的温湿度控制,确保物料干燥均匀,提高产品质量和稳定性。易于维护:模块化设计,便于日常维护和故障排查,减少设备停机时间。环保高效:高效的除尘系统和节能技术,减少废气排放,符合环保标准,助力企业实现绿色生产。High processing efficiency: The combination of steam tube bundle system and rotary drying process significantly improves the drying speed, shortens the production cycle, and meets the needs of large-scale production.Energy saving and emission reduction: Optimized thermal energy utilization and low energy consumption design effectively reduce production costs and environmental burden.Quality assurance: Precise temperature and humidity control ensures uniform drying of materials and improves product quality and stability.Easy maintenance: Modular design facilitates daily maintenance and troubleshooting, reducing equipment downtime.Environmentally friendly and efficient: The efficient dust removal system and energy-saving technology reduce exhaust emissions, meet environmental protection standards, help enterprises realize green production.

该化工企业主要生产化肥及其他化工产品,生产过程中涉及大量的湿物料处理。由于传统烘干设备效率低、能耗高,物料干燥效果不理想,企业面临生产成本高和能耗过大的问题。为此,该公司引入了金万泓机械的蒸汽管束旋转干燥机,来提升干燥效率、降低能耗。金万泓机械为其提供了一台定制的蒸汽管束旋转干燥机。该设备利用蒸汽作为热源,配备高效的管束传热系统,通过旋转滚筒使物料充分接触加热管束,均匀吸收热量,快速蒸发水分,从而实现高效的干燥过程。高效传热:由于蒸汽管束结构的高效传热,设备干燥效率提升了50%,物料水分能够迅速蒸发,显著缩短了干燥周期。节能降耗:使用蒸汽作为热源,大幅减少了燃料消耗,能源成本降低了20%。同时,蒸汽的循环使用进一步提高了能源利用效率,降低了整体能耗。环保优势:设备运行过程中几乎没有废气排放,环保性能显著提升,帮助企业达到了更高的环保标准,获得了环保相关认证。物料品质保证:烘干后的物料品质大幅提高,均匀性更好,确保了化工产品生产的后续工序质量稳定。客户表示,该蒸汽管束旋转干燥机在干燥过程中表现出高效、节能、环保等显著优势,设备运行稳定,减少了停机时间和维护成本。干燥后的物料品质大幅提升,整体生产流程更加顺畅,企业生产效能和经济效益显著提高。这个案例展示了金万泓机械的蒸汽管束旋转干燥机如何在化工行业中帮助客户实现高效干燥、降低能耗,并提升了物料处理的质量和环保表现。Customer name: A chemical enterprise in JiangsuIndustry: Chemical industryThe chemical enterprise mainly produces fertilizers and other chemical products, the production process involves a large number of wet materials processing. Due to the low efficiency and high energy consumption of traditional drying equipment, the drying effect of materials is not ideal, and the enterprise faces the problems of high production cost and excessive energy consumption. To this end, the company has introduced Jinwanhong Machinery's steam tube bundle rotary dryer to improve drying efficiency and reduce energy consumption.Jinwanhong Machinery provided a customized steam tube bundle rotary dryer for it. This device uses steam as a heat source and is equipped with an efficient tube bundle heat transfer system. By rotating the drum, the material fully contacts the heating tube bundle, uniformly absorbs heat, and quickly evaporates moisture, thereby achieving an efficient drying process.High-efficiency heat transfer: Due to the efficient heat transfer of steam tube bundle structure, the drying efficiency of the equipment has been increased by 50%, and the moisture of the material can be evaporated rapidly, which significantly shortens the drying cycle.Energy saving and consumption reduction: Using steam as the heat source significantly reduces fuel consumption and energy costs by 20%. Meanwhile, the cyclic use of steam further improves energy utilization efficiency and reduces overall energy consumption.Environmental advantages: During the operation of the equipment, there are almost no exhaust emissions, and the environmental performance is significantly improved, helping the enterprise achieve higher environmental standards and obtain environmental related certifications.Material quality assurance: The quality of the dried material is greatly improved with better uniformity, ensuring stable quality in the subsequent processes of chemical product production.The customer stated that the steam tube bundle rotary dryer exhibits significant advantages such as high efficiency, energy saving, and environmental protection during the drying process. The quality of the dried material is greatly improved, the overall production process is smoother, and the production efficiency and economic benefits of the enterprise are significantly improved.This case shows how the steam tubebundle rotary dryer of Jinwanhong Machinery can help customers in the chemical industry to realize high efficiency drying, reduce energy consumption, and improve the quality of material processing and environmental performance.